As Northern Europe’s leading tool manufacturer, we make world-class tools and prototypes. We work with several methods to achieve the best results when the tool is to take its physical form. One of these methods is milling. At Lidhs Tooling, we work with CNC milling (Computer Numerical Control), which means that the milling machine is computerised.

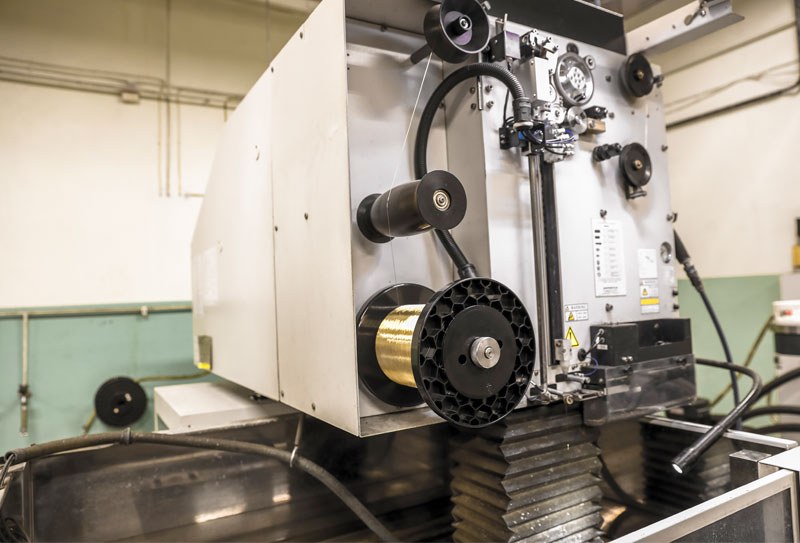

CNC milling is part of our toolmaking process, used to cut and create flat and contoured surfaces on a tool part. With CNC milling, the milling program is programmed in a CAM program to determine how a component should be processed. The milling program then controls the milling machine automatically. The workpiece is made by cutting into the material with rotary tools.

Lidhs Tooling’s machinery pool contains six milling machines with a working area of up to 3,200 x 2,100 x 920 mm. These machines allow us to mill the components of a tool and help other industrial companies in Sweden with subcontracting.

Palettsystem PH 150 – Higher Capacity

- Machining of complex workpieces in a single setup

- Lower machining costs due to reduction of fixtures and use of standard tools, etc.

- High-precision machining due to elimination of manual re-clamping operations

- Reduced machining time through integration of additional processes

- Process optimization: Ideally suited CAD/CAM and automation solutions