Quality assurance and quality control are a fundamental part of our business. And it has been that way in all the years we have been making tools. Lidhs Tooling has been part of Swedish industry for over 50 years, with a high level of competence and extensive experience as a result. Our goal has been to create a cost-effective and sustainable process that does not compromise on quality. And that is precisely how we produce our tools today – with a cost-effective process that creates tools of the highest quality for the engineering industry.

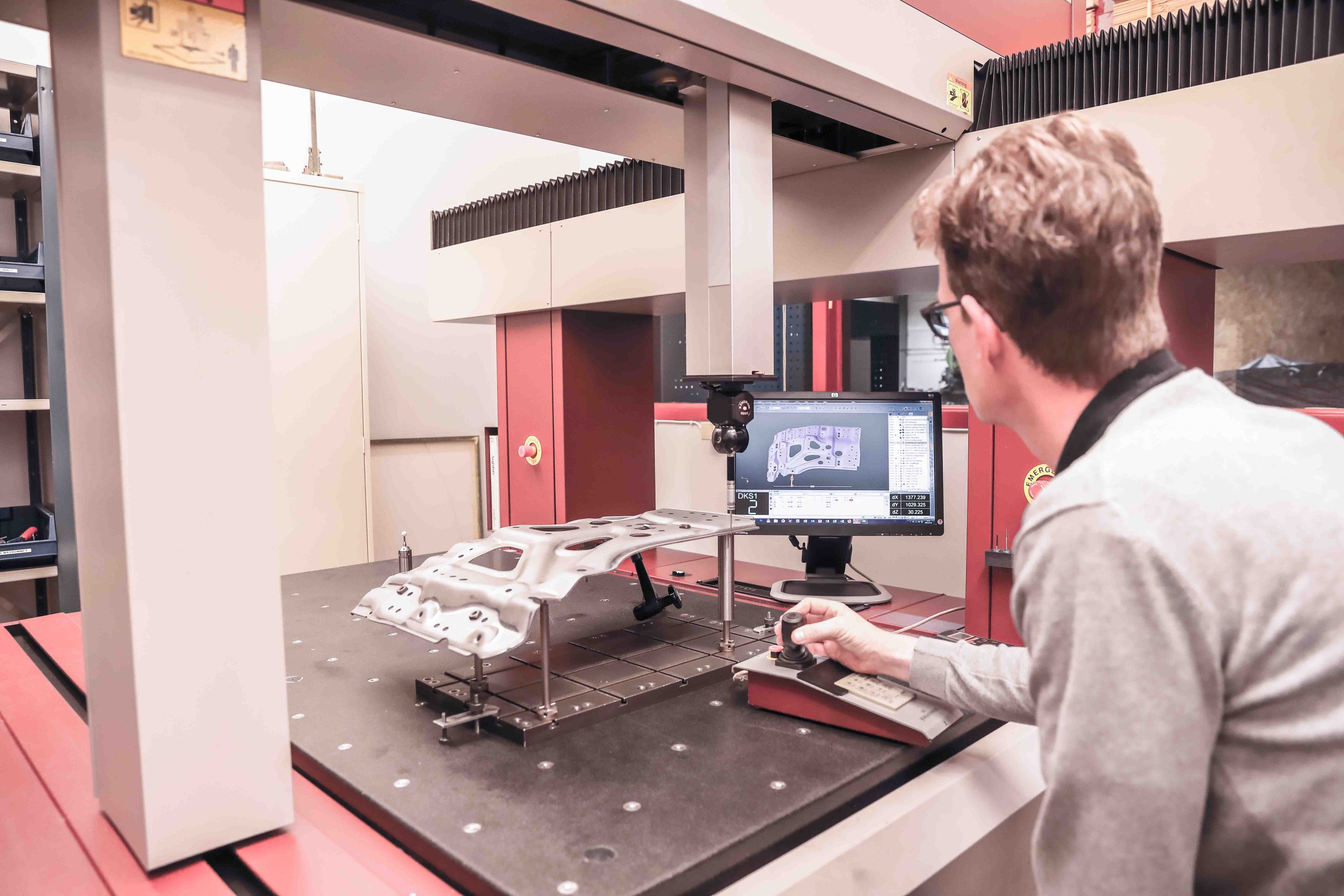

We check the quality of our tools at several stages. During the manufacturing of the tool, its design is simulated several times to obtain information and results on how the solution will work. Using that information, the design of the tool is tweaked until the simulation produces an acceptable result. When the simulation is complete, and the tool parts have been made and assembled, a test run is carried out. This is done in our presses, where we have access to a pressing force of up to 630 tonnes. Finally, we use measuring machines that measure the tool-produced sheet metal part to check the quality. The measuring machine checks that the sheet metal part matches both the digital model and the requirements specification according to the detailed drawing. When all parts match, the tool is complete and ready for delivery.