At Lidhs Tooling, we got off to an early start with wire cutting machines in our tool manufacturing, acquiring our first EDM machine back in 1978. This has given us more than 45 years of experience and extensive expertise when it comes to working with EDM.

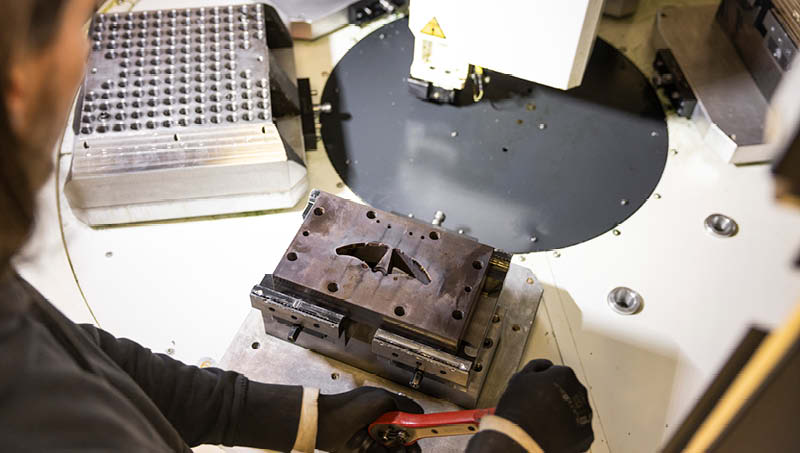

EDM is very much part of the toolmaking process. It is used to cut metal with an electrically charged strand of brass wire. Through the discharging of sparks, the wire can cut away material from a workpiece. The method generates low force on the workpiece, making it suitable for both fragile components and for coarse or hardened materials. The use of EDM makes it possible to produce advanced shapes with high precision.

In our state-of-the-art machinery pool, there are four EDM machines, of which the largest working area is 800x600x320 mm. At Lidhs, we have three employees who specialise in EDM and who use it to produce advanced tool parts and components every day – components that are then assembled to become forming tools for production in the manufacturing industry.